Advantages of Extended Color Gamut Printing

In the world of printing, color accuracy is crucial. Extended color gamut printing offers a solution to achieve vibrant and precise colors. This advanced technique expands the range of colors beyond the traditional CMYK process.

Print shop owners face challenges in maintaining consistent print quality. Extended gamut printing addresses these issues by providing more accurate color reproduction. It reduces the need for costly spot colors, leading to significant cost savings.

Understanding the benefits of extended color gamut printing can transform your business. It enhances customer satisfaction and operational efficiency, ensuring superior print quality.

Understanding Color Gamut in Print

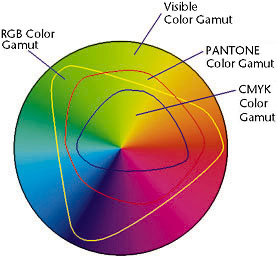

Color gamut refers to the complete range of colors that can be reproduced by a printing device. In traditional printing, the CMYK process — utilizing cyan, magenta, yellow, and black inks — serves as the standard. However, it restricts the ability to replicate certain vibrant hues.

To surpass these limits, extended color gamut printing expands the available color palette. This involves adding extra inks, such as orange, green, and violet. The outcome is a broader spectrum of colors, bringing printed images to life with more accuracy and vibrancy. This technique offers significant benefits to print professionals seeking enhanced color reproduction. Notably, it reduces the necessity for expensive spot colors. As a result, the process becomes more cost-effective while maintaining high-quality standards.

Understanding this concept is crucial for print industry professionals aiming to enhance print quality. By broadening color reproduction capabilities, businesses can meet and exceed client expectations. Key elements to remember about color gamut printing include:

- Limited color range in CMYK

- Importance of additional inks for expansion

- Benefits for achieving accurate and consistent prints

- Reduction in the need for costly spot colors

How Extended Gamut Printing Works: The Science Behind the Process

The key to the success of extended gamut printing lies in incorporating additional ink colors into the traditional CMYK set. This expanded palette allows printers to achieve a more extensive range of colors and finer detail.

The science behind this technology leverages advanced color separations. By using inks like orange, green, and violet, printers mimic colors that were previously only attainable through specific spot inks. Each ink in the expanded set is carefully calibrated to work harmoniously with others, resulting in smoother and more vivid prints.

In terms of execution, the process often requires:

- Advanced software for color separations

- Precise calibration of printing equipment

- Regular maintenance and adjustment of ink profiles

These factors contribute to the production of prints with exceptional color accuracy and vibrancy. By understanding the mechanics, print professionals can produce visually appealing and consistent results, which are crucial for satisfying discerning clients.

Key Advantages of Extended Color Gamut Printing

Extended color gamut printing offers several compelling advantages that significantly enhance print operations. One of the primary benefits is the ability to produce more vibrant and accurate colors. This capability allows for superior color matching, particularly critical for brand consistency.

Another advantage is the reduction in the need for spot colors, which in turn increases cost-efficiency. By utilizing an extended set of inks, printers can replicate a wider array of colors without additional custom inks. Utilizing spot colors often requires inks to be changed between jobs, which requires extra time between each run. With extended gamut colors, press operators are able to print multiple jobs with the same extended gamut inks. This leads to tangible cost savings in terms of inventory and waste.

The consistency of print runs also improves with extended gamut printing. By minimizing variability, the technology ensures that colors remain uniform across different batches, enhancing reliability. This is particularly beneficial for high-volume projects where maintaining consistent output is challenging.

Moreover, extended gamut printing supports high-quality photographic and artistic reproductions. The expanded color range means intricate designs are captured with greater fidelity, appealing to clients demanding precision.

Significantly, the environmental impact of printing operations can be reduced. Extended gamut technology often involves less ink waste, contributing to sustainable practices. As businesses increasingly prioritize eco-friendly operations, this is a noteworthy advantage.

In summary, key benefits of extended color gamut printing include:

- Enhanced color vibrancy and accuracy

- Cost savings from reduced spot color use

- Improved consistency across print runs

- High-quality reproduction of intricate designs

- Reduced environmental impact through less ink waste

These advantages combine to make extended gamut printing a valuable investment for businesses aiming for excellence and innovation in print quality.

Cost Savings and Operational Efficiency

Implementing extended color gamut printing offers significant cost savings by minimizing the reliance on expensive spot colors. With a broader palette available, businesses can achieve desired hues without custom inks, reducing overhead.

Operational efficiency sees marked improvement as well. The reduced need for frequent ink changes decreases downtime, streamlining the production process. This efficiency translates into faster job completions, a vital factor in high-demand environments.

Moreover, extended gamut printing enables better inventory management. By eliminating multiple spot colors, print shops can optimize storage needs, reducing both clutter and waste. This leads to a more organized and efficient workspace, enhancing productivity.

In summary, key cost-saving and efficiency-enhancing aspects include:

- Decreased dependency on custom spot inks

- Streamlined production with fewer ink changes

- Optimized inventory and storage management

These factors collectively enhance a print shop’s operational efficacy, supporting both economic and efficient production methods.

Enhanced Print Quality and Color Accuracy

Extended color gamut printing significantly boosts print quality by offering a broader spectrum of colors beyond the standard CMYK process. This expanded range results in more vibrant and true-to-life images, elevating the aesthetic appeal of printed materials.

The accuracy of color reproduction is equally impressive. By incorporating additional inks like orange, green, and violet, printers can achieve precise color matches with greater consistency across different substrates. This consistency reduces the need for costly reprints and enhances brand recognition.

Another benefit lies in the ability to accurately reproduce complex and intricate designs. The expanded color range allows for subtle color variations, essential for detailed graphics and high-quality photographs or logos. This capability translates into superior product packaging and marketing materials.

Key enhancements in print quality and color accuracy include:

- Expanded color range beyond CMYK

- Improved consistency in color reproduction

- Precise matches for complex designs

These enhancements are crucial for businesses aiming for top-tier visual presentation and client satisfaction.

Applications of Extended Gamut Printing

Extended gamut printing offers diverse applications across various industries. Its ability to produce vibrant and accurate colors makes it ideal for high-impact marketing materials and product packaging. These materials benefit greatly from the expanded color palette, ensuring they capture attention and convey brand messages effectively.

In addition to marketing, artistic projects benefit from this technology. Photographers and artists can achieve detailed and subtle color transitions that bring their works to life. This precision is crucial for reproducing delicate hues found in paintings and intricate graphic designs.

Moreover, extended gamut printing supports specialized fields such as branding and signage. Here, precise color matching is paramount to maintain consistency and brand integrity. The ability to use additional inks enables exact reproduction of brand-specific colors.

Key use cases include:

- High-impact marketing materials

- Artistic and photographic reproductions

- Branding and signage

These applications demonstrate the versatility and wide-ranging benefits of extended gamut printing in producing superior print products.

Implementation Considerations: Equipment, Training, and Workflow

Implementing extended gamut printing necessitates careful planning. First, evaluate your current equipment. Some existing systems may integrate easily with this technology, while others might need upgrades. It’s crucial to partner with reliable suppliers to ensure quality and compatibility.

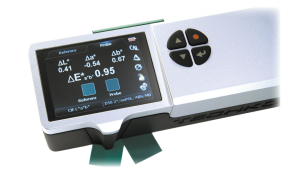

When working with an extended number of inks and colors, it can be easy to drift out of tolerance on press. To combat this, Techkon USA offers a wide range of color management solutions and technology. These devices, such as Techkon’s SpectroDens 4, are crucial for the extended gamut process. When looking to maintain the highest quality and intricacy with designs, it is important to utilize color measurement tools to ensure that jobs are meeting client expectations and standards.

Training is another essential component. Staff should be well-versed in new processes and tools. This may involve comprehensive training sessions or workshops. Expertise in color management is key to achieving optimal results. Techkon offers hands-on training for users who are new to utilizing Techkon color measurement solutions.

Efficient workflows are also critical for successful implementation. Streamline processes by minimizing manual color adjustments. Develop clear protocols to optimize productivity and ensure consistent quality across print runs.

Consider these implementation factors:

- Equipment evaluation and upgrades

- Color measurement technology

- Staff training for proficiency

- Workflow optimization

By addressing these aspects, your transition to extended gamut printing can be seamless and beneficial.

Overcoming Challenges and Ensuring Success

Successfully adopting extended color gamut (ECG) printing requires tight process control. Investing in advanced color measurement tools, such as Techkon’s automated scanning spectrophotometer, SpectroDrive, is the perfect complement for any offset printing environment and ensures fast and accurate color measurements. Furthermore, for flexo printers, Techkon’s inline scanning spectrophotometer allows press operators to get real-time color measurements at full production speeds. This is extremely important with ECG printing as spot color inks are replaced with process color builds that are designed to match the original brand or spot colors. Brands care a great deal about their special colors, as brand recognition and integrity are important. Therefore, when replacing spot colors with ECG process versions, it is critical to ensure the density and dot gain are measuring correctly throughout the entire press run. With inline scanning solutions, like the SpectroVision, press operators are able to see color measurements in real-time, while the press is running. This allows them to make necessary adjustments without the need for costly remakes or wasted substrate.

Conclusion: Is Extended Color Gamut Printing Right for Your Business?

Deciding to adopt extended color gamut printing depends on your business goals. If achieving superior color quality and differentiation is important, this technology is worth considering. It can enhance print quality and expand service offerings.