Color Measurement Devices

Densitometers and Spectrophotometers: Handhelds, Scanners, Inline, Closed Loop

Color measurement instruments are tools such as colorimeters or spectrophotometers that are used to quantitively analyze color. Spectrophotometers are used for detailed color analysis while colorimeters are used for basic color comparisons. They both ensure consistent print quality and accurate color reproduction.

What Instrument is Used to Measure Color?

Spectrophotometers and colorimeters are the primary color measurement instruments used. Each has unique features and applications.

These tools are essential for maintaining quality across various printing jobs. They capture data about color and light, helping to ensure consistency.

Here’s a quick overview of the main types:

- Spectrophotometers: Offer detailed wavelength data; used for advanced color analysis.

- Colorimeters: Simpler and cost-effective; suitable for basic color checks.

What is the Difference Between a Colorimetric and a Spectrophotometer?

In basic terms, colorimeters are tailored for simplicity. They work by mimicking human vision by using red, green, and blue filters to assess color. Colorimeters are simpler and cost-effective, making them suitable for basic color checks.

Spectrophotometers analyze color by measuring light across the spectrum. They provide a high-precision and detailed profile of a color’s attributes, making them suitable for tasks requiring precision and flexibility.

Consider these key differences:

- Purpose: Colorimeters for basic matches, spectrophotometers for detailed analysis.

- Measurement: Colorimeters use RGB filters; spectrophotometers use wavelength data.

- Cost: Colorimeters are typically more affordable.

- Precision: Spectrophotometers offer greater accuracy and versatility

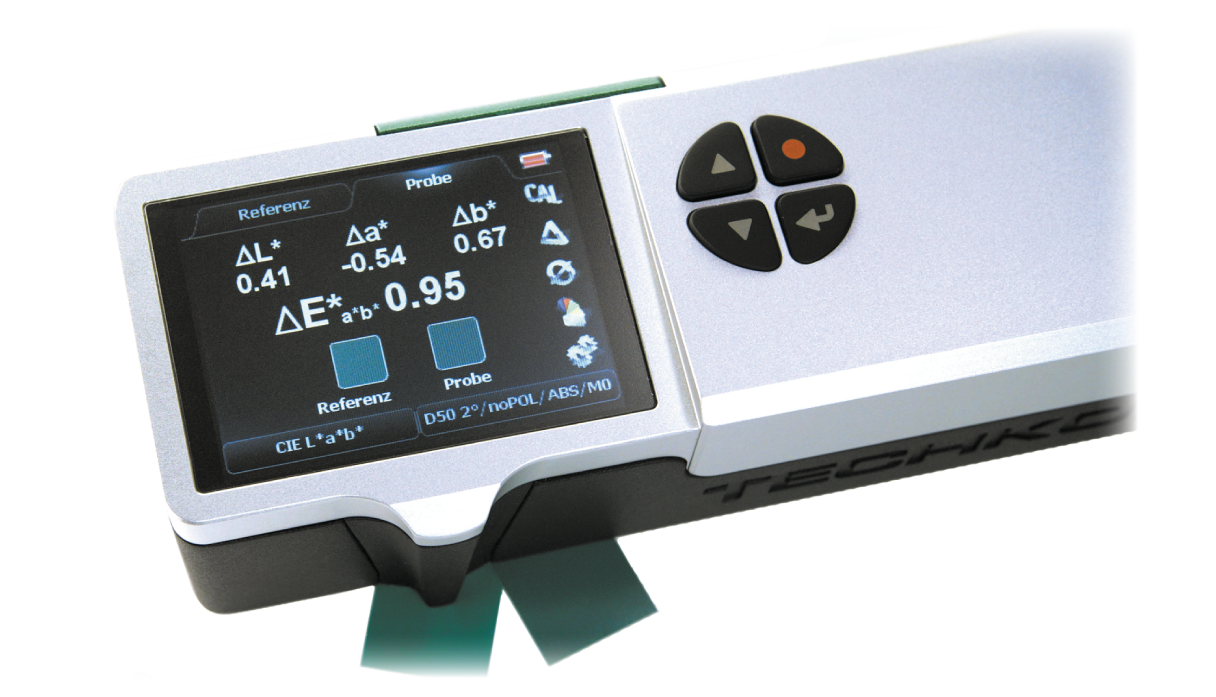

- All-in-one, best-in-class Color SpectroDensitometer for fast, accurate, and complete color measurement

- Measure spot colors and color density or scan color bars

- View density variation across press width

- Verify proofs against ISO and other standards

- Maintain G7 neutral values with control strip

- Combined Color Spectrophotometer and Color Densitometer allows for extensive evaluation with a single Color Measurement Tool

- Ergonomic one-handed operation and connects to Wi-Fi

- Precise Color Densitometer for ink density measurement

- Rugged design with milled aluminum body

- Optical engine uses a new high-precision color sensor

- Measure CMYK color density, dot gain and grey balance

- Integrated 4X magnifier lens with LED illumination

- Measures film transmission

- 10,000 readings on a single charge

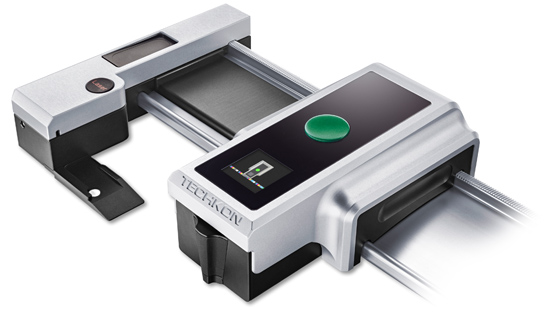

- Automatic Scanning Color Spectrophotometer – measures a 40-inch press’s efficiency in less than 8 seconds

- Device is automatically guided on rails

- Easily pick up device for spot checks and put back on automated track

- Color management software includes G7 control, and recommendations for ink color density adjustments

- Customers see 30% productivity increase

- Upgradeable to a PressLink closed-loop color control software/hardware system when ready to modernize further

- Modernize your offset press and improve profitability

- Ink presetting software helps reduce make ready time

- Closed Loop Color Control Software & System – automatically adjusts ink keys on console

- Includes SpectroDrive for automated scanning of color bars

- Integrations with press consoles from Heidelberg, Komori, KBA, Manroland, and more supported

- Reduce waste by closing the loop

- Typical savings of $200,000 per year per press

- Advanced but easy to use Handheld Color Scanning Device

- Measure density and color values of process and

spot colors - Wheels on the device ensure a straight run – rolls easily

by hand - Still measures a 40-inch press in 8 seconds

- Data is transferred to PC within seconds

- Control strip can be placed anywhere on the sheet

- Software includes features for G7 and ink color density control

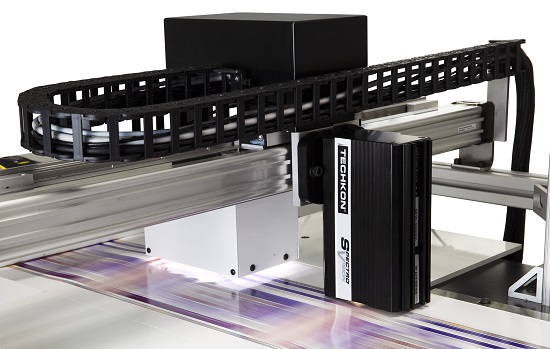

- Measure a flexographic or digital press control strip containing up to 100 color patches in a single printed impression

- Inline Automated Color Spectrophotometer is guided by a high-resolution digital camera to find the exact location of color patches, color bars, and any specific in-image measurement location

- Continuous improvement of color accuracy and consistency

- Cut down on make ready times – Improve output of each shift

- Affordable and easy-to-install. Fast ROI

- Turnkey service and ongoing support