Color Measurement in the Printing Industry: A Complete Guide

In the world of professional printing, precision is everything. Whether producing packaging, marketing materials, or high-end publications, the colors you see on the press sheet must match the intended design—every time. This is where color measurement comes into play. By using specialized color measurement instruments, printers can achieve consistent, accurate results, reduce waste, and improve customer satisfaction.

In this guide, we’ll cover the essentials of color measurement, explore the tools used in the printing industry, and answer key questions about Delta E, LAB values, and industry standards.

What is Color Measurement?

Color measurement is the process of quantifying and evaluating the colors of printed materials using objective, numerical data rather than subjective human vision.

In printing, color measurement is critical because visual inspection alone cannot detect subtle shifts in hue, saturation, or lightness. A trained press operator may notice when a color is “off,” but without numbers, adjustments are guesswork.

Using color measurement devices—such as a color measurement spectrophotometer—printers can measure the exact color values of inks, paper, and printed output. These measurements are then compared to defined targets, allowing for precise adjustments during production.

What Are Color Measurements?

Color measurements refer to the numerical values assigned to a specific color sample. These numbers can represent:

- L* – Lightness (from black to white)

- a* – Green to red axis

- b* – Blue to yellow axis

Together, these form the LAB color space, an industry-standard method for describing color in a way that matches human perception.

What is LAB in Color Measurement?

In color measurement, LAB refers to the CIE LAB color space, developed by the International Commission on Illumination (CIE). It is a device-independent model, meaning the color values remain consistent regardless of the device used to capture or display them.

- L* (Lightness) measures brightness from 0 (black) to 100 (white).

- a* measures position between green (-a) and red (+a).

- b* measures position between blue (-b) and yellow (+b).

Using LAB values allows printers and designers to communicate precise color targets without ambiguity, making it one of the most important systems for color measurement solutions in print production.

What is Delta E?

Delta E (ΔE) is the numerical value representing the difference between two colors. In printing, Delta E is used to compare the measured color against a target color.

A lower Delta E means the two colors are closer in appearance. Common tolerances in printing are:

- ΔE ≤ 1.0 – Virtually indistinguishable to the human eye.

- ΔE ≤ 2.0 – Barely distinguishable for untrained eye.

- ΔE ≤ 2.5 – Acceptable for most commercial printing.

- ΔE ≥ 5.0 – Noticeable color difference; usually unacceptable

By using a color measurement spectrophotometer, printers can track Delta E values in real time and make adjustments before deviations lead to costly reprints.

What is the Standard Color Measurement?

The printing industry relies on international standards to ensure consistent results across devices, substrates, and production sites. The CIE LAB color space is the most widely used standard for color control in print.

Other important standards include:

- ISO 12647 – Defines color measurement and control for different printing processes

- GRACoL and SWOP – North American print standards

- Fogra – European print standards

Using these guidelines, printers can ensure that colors match customer expectations, regardless of where or how the job is printed.

What is a Color Measurement Device?

A color measurement device is any instrument designed to evaluate and quantify color using standardized methods. In printing, these devices help maintain consistency from proof to press to final output.

Common devices include:

- Spectrophotometers – Measure the full spectrum of light reflected from a sample.

- Spectrodensitometers – Combine spectral and density measurements for print-specific applications.

- Colorimeters – Measure colors based on filtered RGB sensors (less precise than spectrophotometers but faster).

- Densitometers – Used to measure the thickness of C, M, Y, and K inks using specific filters.

Choosing the right device depends on your application, accuracy requirements, and production environment.

What is the Instrument Used to Measure Color in Printing?

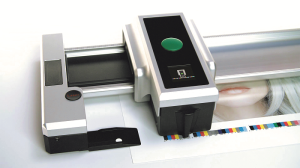

The primary instrument used to measure color in the printing industry is the spectrophotometer. A color measurement spectrophotometer captures the full spectral data of a printed sample, allowing it to calculate accurate LAB values and Delta E differences.

There are different types of measurement tools for printing:

- Handheld spectrophotometers – Portable devices used for spot checks during press runs.

- Scanning spectrophotometers – Measures entire sheets or color bars automatically.

- Inline color measurement devices – Integrated into printing presses to continuously monitor color in real time.

Inline Color Control in Printing

Inline color control is a game-changer for high-speed, high-volume print environments. Instead of manually checking color samples at intervals, inline systems continuously monitor the entire print run.

Advantages of inline measurement:

- Instant feedback on color drift

- Reduced waste and downtime

- Greater consistency across long runs and repeat jobs

Inline systems are especially valuable in packaging, label printing, and other applications where exact brand color reproduction is critical.

Why Accurate Color Measurements Matter in Printing

Inconsistent color can damage brand perception, lead to reprints, and waste valuable resources. By investing in reliable color measurement instruments and solutions, printers can:

- Meet brand color standards with confidence

- Reduce make-ready times

- Minimize costly color disputes with customers

- Achieve predictable results across multiple presses and facilities

Final Thoughts

From handheld color measurement tools to fully automated inline devices, today’s printing industry has access to powerful technology for achieving precise, repeatable color.

By understanding LAB values, monitoring Delta E differences, and adhering to standard color measurement practices, printers can deliver consistent quality that meets the highest professional standards.

Whether you’re running offset, flexographic, or digital presses, implementing the right color control solutions will pay off in efficiency, quality, and customer satisfaction.